Sheet Metal Molds

Sheet Metal Molds

The Place Where Craftsmanship Meets Technology in Mold Production

Kalen Kalıp emerges as a versatile powerhouse in a production environment that is as dynamic as it is diverse. We offer a wide range of molds to meet every need with our wide portfolio extending to the automotive, heating-cooling, electrical-electronic and energy sectors.

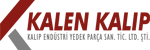

Mastery of Shape and Form

Our sheet metal molds are the industry benchmark when it comes to machining complex and durable parts. Focusing on durability and precision, these molds are perfect for creating components that can withstand the rigors of everyday use in the automotive or energy industries.

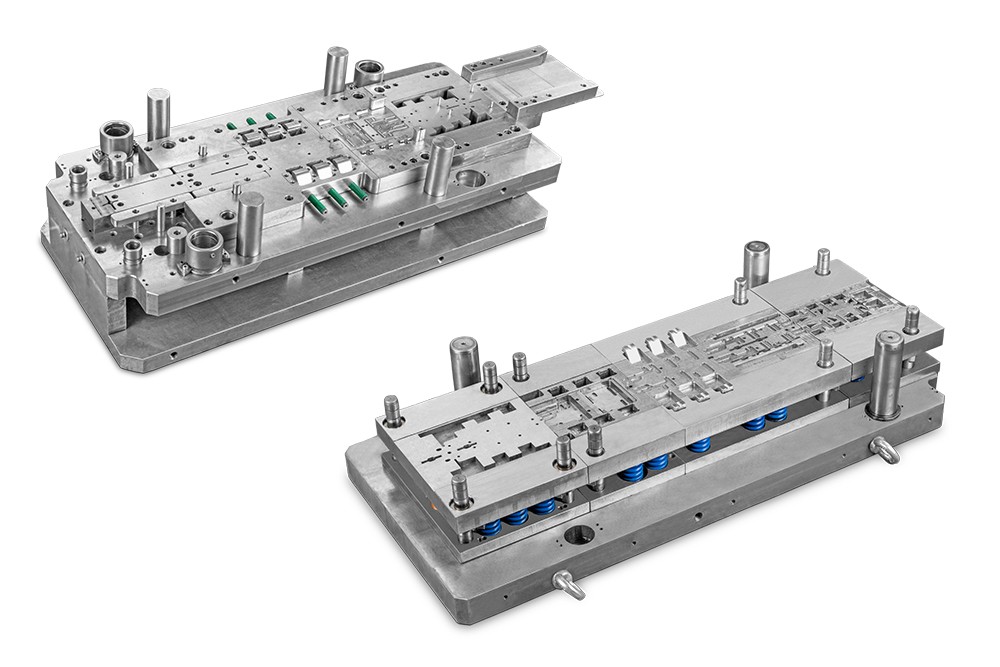

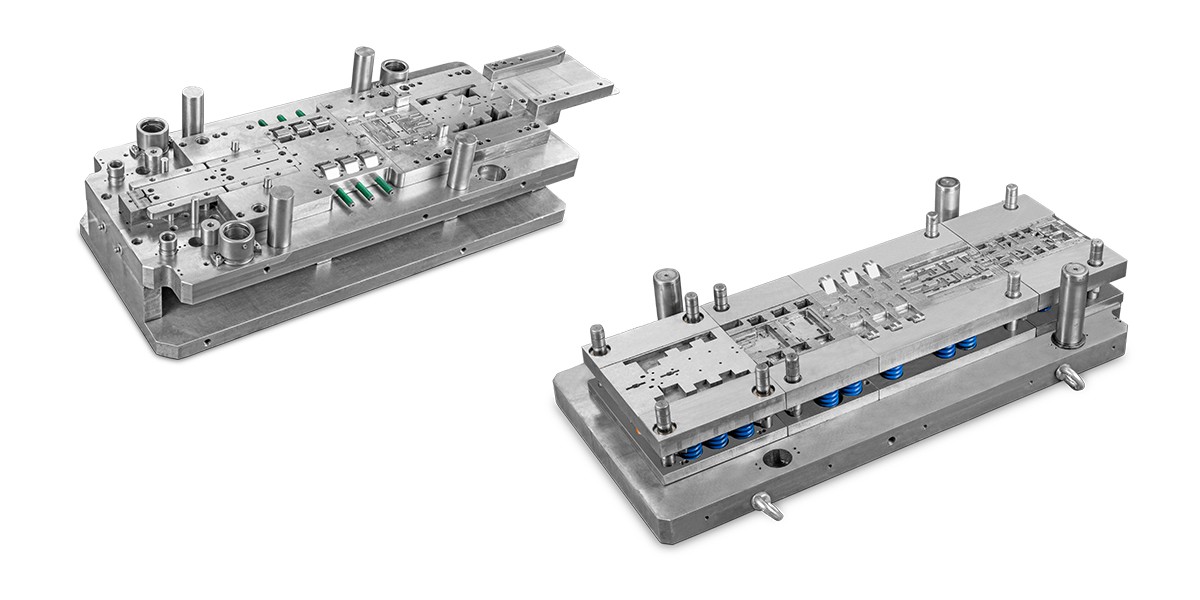

Progressive Patterns

Compatibility of Multiple Operations

Imagine a die that can perform multiple operations in a single pass. This is the power of our progressive patterns. Suitable for high volume production needs, these molds save time without sacrificing quality, which is vital in fast-growing industries such as electrical and electronics.

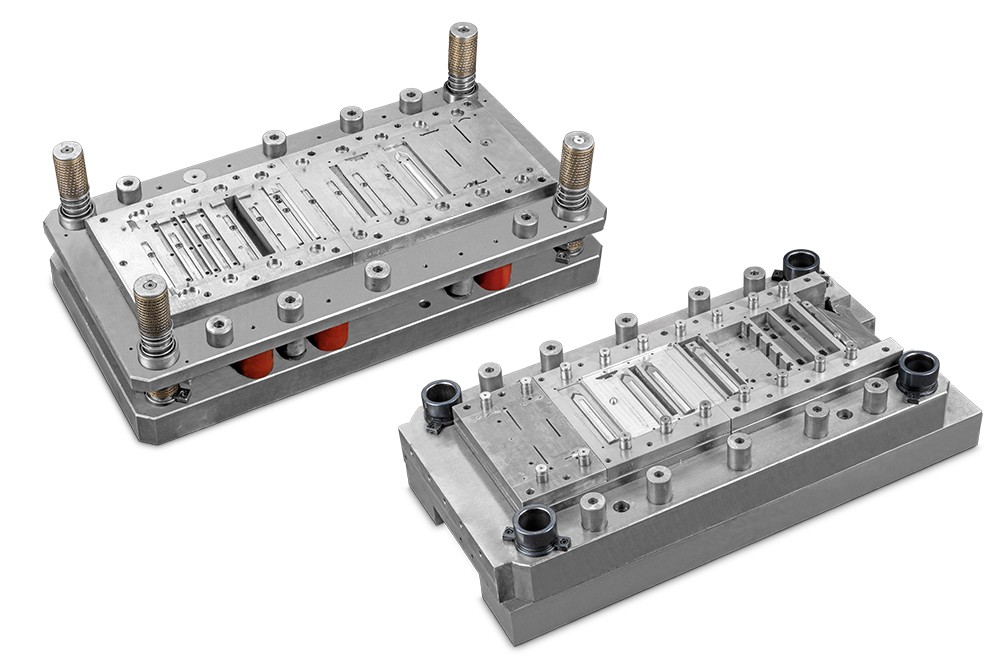

Cutting-Bending Dies

Same Precision on Every Curve

Our cutting-bending dies are designed to cut and bend metal sheets with high precision. Ideal for industries requiring complex geometries such as heating-cooling systems, these molds are a testament to our ingenuity and technological superiority.

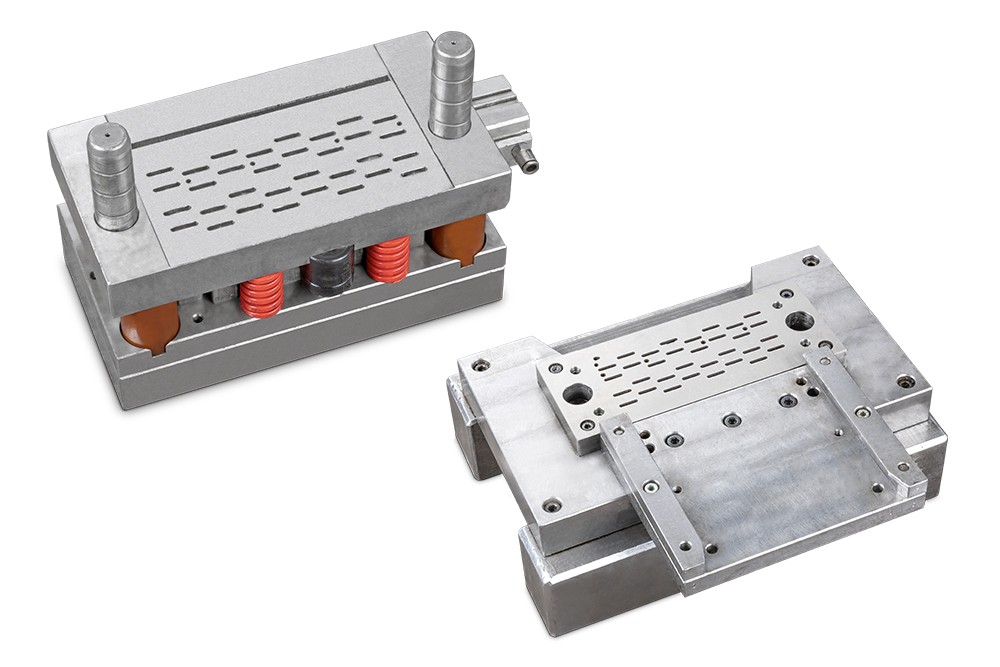

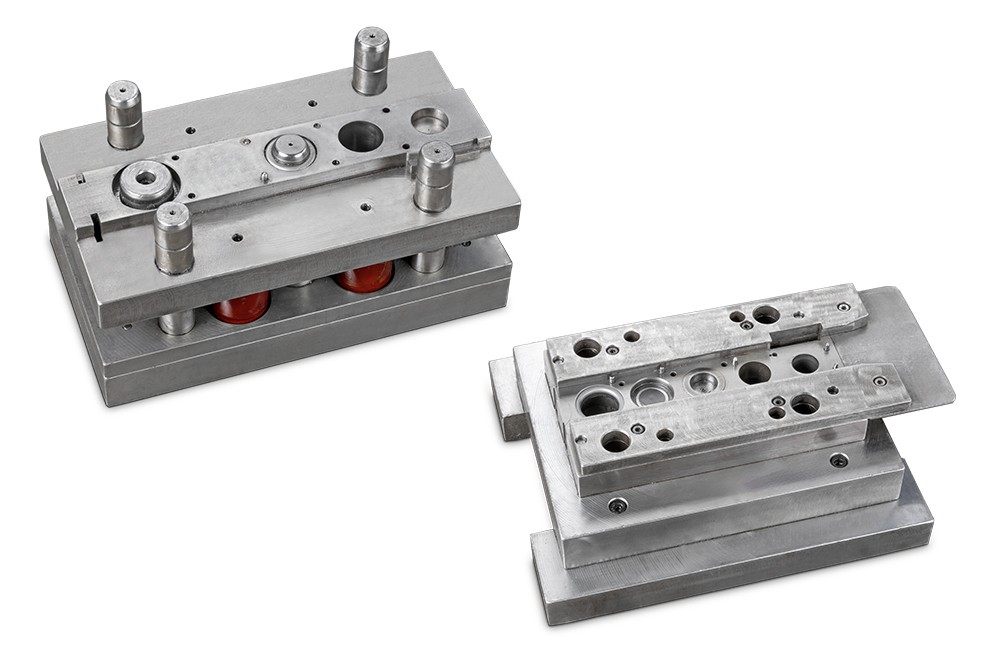

Spinning Dies

Continuous Smoothness

In the metal forming area, spinning dies easily create large quantities of seamless parts. Plastering Dies, which provide the production of plastered products by pressing and drawing on metal by pressing machines of varying tonnage and power according to the product, are used in applications that require perfect lines such as special cooling systems or advanced electrical components.

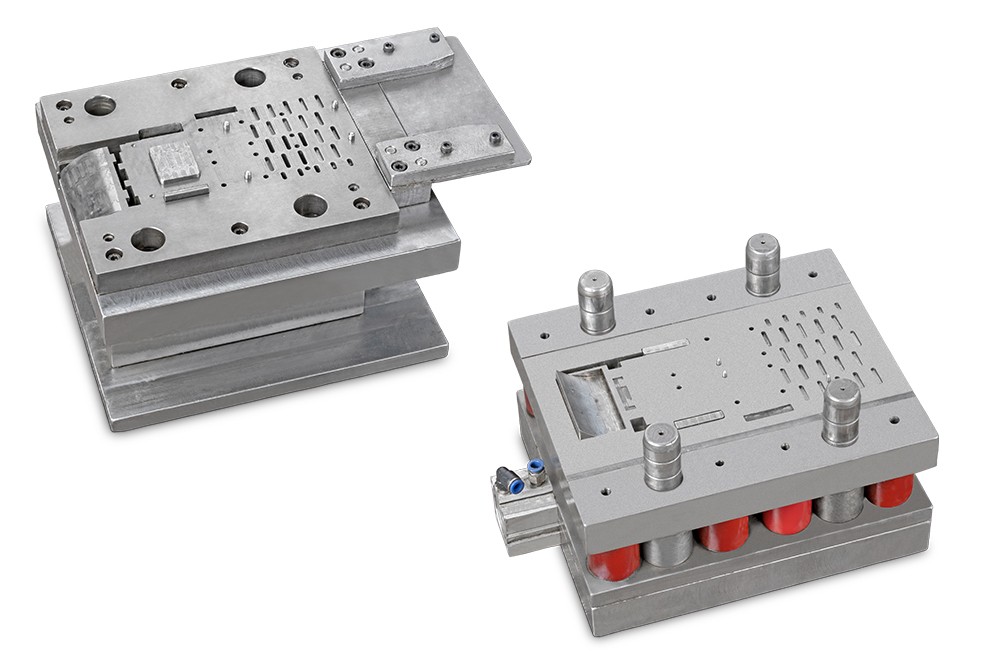

Metal Working Dies

Beyond Standard Metrics

We go beyond a one-size-fits-all solution approach when it comes to metalworking dies. These molds, which are specially prepared for special needs, are the preferred choice for special projects in the automotive and energy sectors where standard molds will not be sufficient.

'Our reputation as a trusted mold maker is based not only on the patterns we create, but also on the relationships we build. We believe in solution-oriented cooperation and mutual growth, and we repeat our company mission by keeping customer and employee satisfaction at the top.'